Aarekies Aarau-Olten AG

The gravel and concrete producer belonging to Jura Holding has heralded a new era in the treatment of aggregates with this new gravel plant in Buchs. The state-of-the-art plant makes Aarekies-Olten AG the leading supplier of sand and gravel in the Aarau region.

Emmi Käse AG

Emmi Käse AG in Kirchberg processes various cheese products from storage to finished items. The conveyor system supports the client with conveyance – from wheels of cheese to the removal of bulk material.

VITO Recycling AG, Soil washing plant

Processing plant sets standards for material recycling - Contaminated mineral construction waste and contaminated soil materials are processed in the soil washing plant. In the process, a maximum number of impurities can be separated.

ARGE GRIMSEL, Gerstenegg treatment plant

Temporary plant at 1,710 metres above sea level. Due to the construction of the new ‘Spitallamm’ replacement dam by Kraftwerke Oberhasli AG (KWO), Frei Fördertechnik AG built a treatment plant on the Gerstenegg Grimsel Pass.

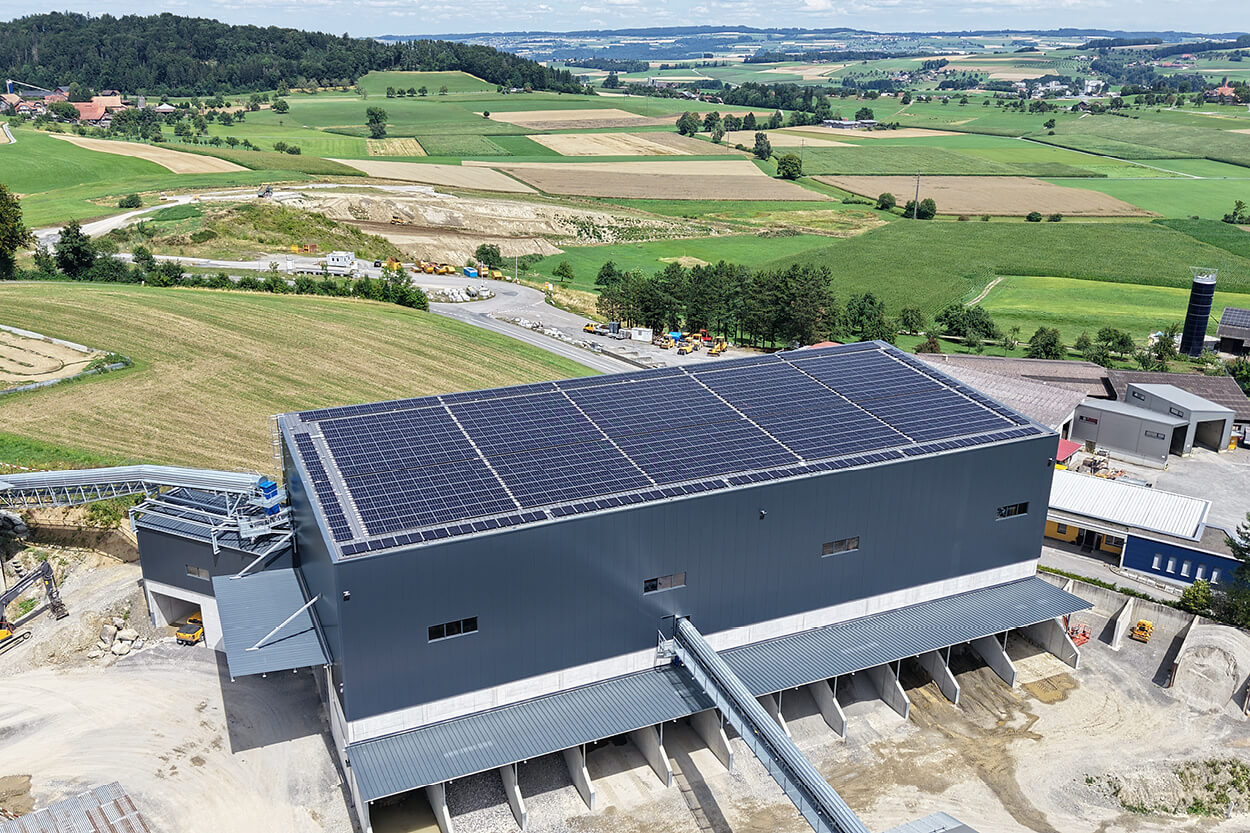

BRT Baustoff Recycling Thurgau AG

Processing plant closes the cycles in concrete production. BRT AG's aim was to close the material cycles in the regional construction sector. Using state-of-the-art technology, mineral materials are processed and the reusable components are recovered as high-quality building materials.

RCO Recycling Center Ostschweiz AG

High-quality building materials thanks to state-of-the-art building materials recycling plant - Frei Fördertechnik AG was responsible for the planning, engineering in close cooperation with RCO, fabrication, assembly, E-MSRL control and commissioning of the building materials recycling plant as a complete turnkey system.

MATISA SA

Innovation with power - machines for track construction and maintenance

Landor AG

Birsfelder Auhafen, a hub on the Rhine river, connects river, rail and road, making for optimal conditions for simple and inexpensive logistics. The unloading station of Landor AG was refurbished for the unloading of cargo ships with power shovels to the new silo with batch feed belt (year of construction 2013). In 2023 we are building a conveyor system in the port of Muttenz to link up with the fertiliser warehouse.

Fortisa AG

Fortisa AG specializes in the industrial production of buns and, in addition to McDonald’s, supplies many customers in the catering and food industries. In order to be able to continue to produce economically, the entire production was modernized.

Micarna SA

The sophisticated concept with stainless steel conveyor technology guarantees maximum hygiene. Frei Fördertechnik AG modernised the existing container conveyor system at the Micarna Group in Ecublens.

Post CH AG, Urdorf

The conveyor system is used for handling during customs processing and for pre-sorting packages. The work process was ergonomically designed and partially automated. At the same time, the quality of the processing was increased and the process has become more cost-efficient.

Flughafen Zürich AG

In addition to the design and finish of the system, user-friendliness plays a crucial role. With an average of 24 million passengers annually, demands on the equipment are extremely high.

Interdiscount & microspot.ch

In order to cope with the increasing volume of online trading, Interdiscount and microspot.ch decided to purchase a fully automatic parcel machine. For the removal route from the parcel machine and for merging with the a conveyor system from Frei Fördertechnik AG was used on the existing line.

BM Betonwerk Malters AG

Conveyor technology for perfect stockpiling - Frei Fördertechnik AG was commissioned with the planning, realisation, assembly and commissioning of the new covered component storage facility. The system is used to store the processed excavated, concrete and mixed demolition components.

Carrière de Sous-Vent

Maximising productivity - The modernisation of the grit processing system has maximised productivity at the gravel plant. Environmental efficiency has been increased and the plant is state of the art in terms of safety and operation.

Conforti SA

State-of-the-art technology - Following this conversion of the plant, the productivity of Carrière de l'Aboyeu has been maximised and fully complies with the latest state of the art in terms of safety and operation.

H2M Exploitation SA

The balancing act between excavation and RC material processing - With H2M, Frei Fördertechnik AG has created a system that is capable of efficiently processing both excavated and RC material. The RC material is freed from impurities by means of a kidney function. The processed end products are fed directly to the concrete centre's silo system.

Makies AG

16 tonnes for the perfect wash - After 40 years of reliable operation at Makies AG in Gettnau, the time has come to replace the entire washing drum. Frei Fördertechnik AG was commissioned with the replacement.

Kieswerk Oldis AG

The path to the circular economy - The extensive new construction of the processing plant enables primary gravel, recycled and excavated materials to be processed and returned to the material cycle as high-quality construction materials.

Surer UPREC AG

Are you still dumping or already washing? Mineral construction waste is processed and classified in our in-house recycling centre. The centre produces high-quality recycled building materials that meet the highest ecological and structural requirements.

Tägerhard Kies AG

Perfect replacement despite structural challenges - The special challenges of the structural conditions and the actual installation of the machines in confined spaces were realised without any problems thanks to our customised solution.

Ziegelei Lauper AG

Ziegelei Lauper AG is part of FBB and is building a new brick plant. Frei Fördertechnik AG created the distribution system in three feeding hoppers and the feed into the press, including dirt bands under the brick plant machinery.

Eberhard Bau AG, EbiMIK

New construction of the EbiMIK LOS 01 Oberglatt building material mixing and demolition processing plant for sustainable ‘urban mining’ with a closed cycle. State-of-the-art crushing and screening plants with a sophisticated robotic sorting line form the first stage of a highly modern building material recycling plant.

Messerli Kieswerk AG, Oberwangen

After 40 years of planning and only 16 months' construction time, the cutting-edge gravel and concrete plant of Messerli Kieswerk AG in Oberwangen was inaugurated in 2013. The new plant replaces two old gravel plants and offers the separate feeding of gravel and moraine material as well as their flawless processing.

Aarekies-Olten AG

The gravel and concrete producer belonging to Jura Holding has heralded a new era in the treatment of aggregates with this new gravel plant in Buchs. The state-of-the-art plant makes Aarekies-Olten AG the leading supplier of sand and gravel in the Aarau region.

Baustoffzentrum Olten/Zofingen BOZ

Optimal connection with 1.2 km of conveyor technology – The newly implemented conveyor technology connects the two plants in Gunzgen and Boningen. This eliminates the need for truck journeys on the road network.

Fuji Packaging GmbH

Fuji Packaging GmbH manufactures packaging machines and has implemented this system on behalf of Fortisa SA in Zuchwil. Fortisa SA makes round and oval bread loaves for a well-known retailer with high quality standards.

Nudelpeter Eierteigwarenfabrik

Nudelpeter Eierteigwarenfabrik Karl Siegel GmbH in Waiblingen (D) specialises in the production of pasta products of all kinds. The conveyor system we manufactured transports different varieties of pasta goods between the various production processes.

Panellino AG

The Panellino AG bakery and confectioner in Cortébert produces bread in large quantities. A conveyor system, which additionally serves as a cooling section, was installed for transporting the loaves from the baking oven on the second floor down to the ground floor.

Mondelez Schweiz Production GmbH

Mondelez Schweiz Production GmbH produces Toblerone chocolate bars in a wide range of shapes and sizes The system transports packaged products via conveyor technology to the moulding system on the one hand, and transports the packaged products away to various secondary packaging systems on the other.

Eisberg AG

Eisberg AG processes vegetables and fruit. The Tageskühler conveyor system is used to temporarily store the delivered products and then distribute them to the workstations. The system is completely rustproof and meets the highest standards of sanitary design.

Ramseier Suisse AG

The history of the Ramseier brand began over 100 years ago. Today, Ramseier is the most popular fruit juice brand in Switzerland. With the new conveyor system, the fresh fruit is accepted and reloaded into troughs.

Rutishauser AG

Rutishauser AG produces potted plants and flowers in its own state-of-the-art greenhouses and supplies most of Switzerland's major distributors. With the newly constructed conveyor system in the preparation area, production is being automated in a further stage. The prepared plants are efficiently picked and placed in trays.

Zweifel Chips & Snacks AG

In order to ensure flawless production of potato chips at Zweifel Chips & Snacks AG, it became necessary to replace a pendulum cup conveyor. Frei Fördertechnik AG was commissioned to engineer and deliver two stainless steel wave edge conveyor belts with cleaning units.

Auhafen Muttenz / Fenaco Genossenschaft

Fenaco planned a new transhipment platform and grain collection point for grain and derivatives in the Auhafen in Muttenz. A new ship unloading and silo facility with integrated rail unloading, rail loading, truck unloading and truck loading with a loading capacity of 250 tonnes/hour for both trucks and rail is to be built. Existing sand silos were converted and a new silo over 70 metres high was erected for the facility. It has a storage capacity of around 40,000 tonnes.

Schweizer Zucker AG

Corrugated edge conveyor system to replace the old chain conveyor system - Due to high maintenance costs, the old chain conveyor system was replaced. Frei Fördertechnik AG provides clear arguments for the use of a new wave edge conveyor belt to the benefit of the customer.

Vigier Beton Mittelland AG

For modern gravel processing. Modern, robust construction adapted to the requirements of gravel processing technology. From engineering to assembly and commissioning – we supplied everything from a single source.

Mifa AG

Mifa AG, headquartered in Frenkendorf, is the largest manufacturer of detergents and edible fats in Switzerland. They produce mainly for Migros. The new high-speed filling system manages to count washing machine tabs and fill them into boxes at a rate of up to 800 tabs per minute.

Saint Gobain Weber AG

Vertical lifts are used in Boningen to transport goods from one building to another. A steel bridge connects the two existing buildings. Eight pallets can be stored on so-called storage sections. The statics of the building have been optimised in this area.

Birchmeier Kies + Deponie AG

Birchmeier Kies + Beton AG has been successfully operating a gravel and concrete plant in Döttingen since October 2016. The expansion in the Hard-Härdli area in Klingnau will secure the regional supply of high-quality gravel in the long term.

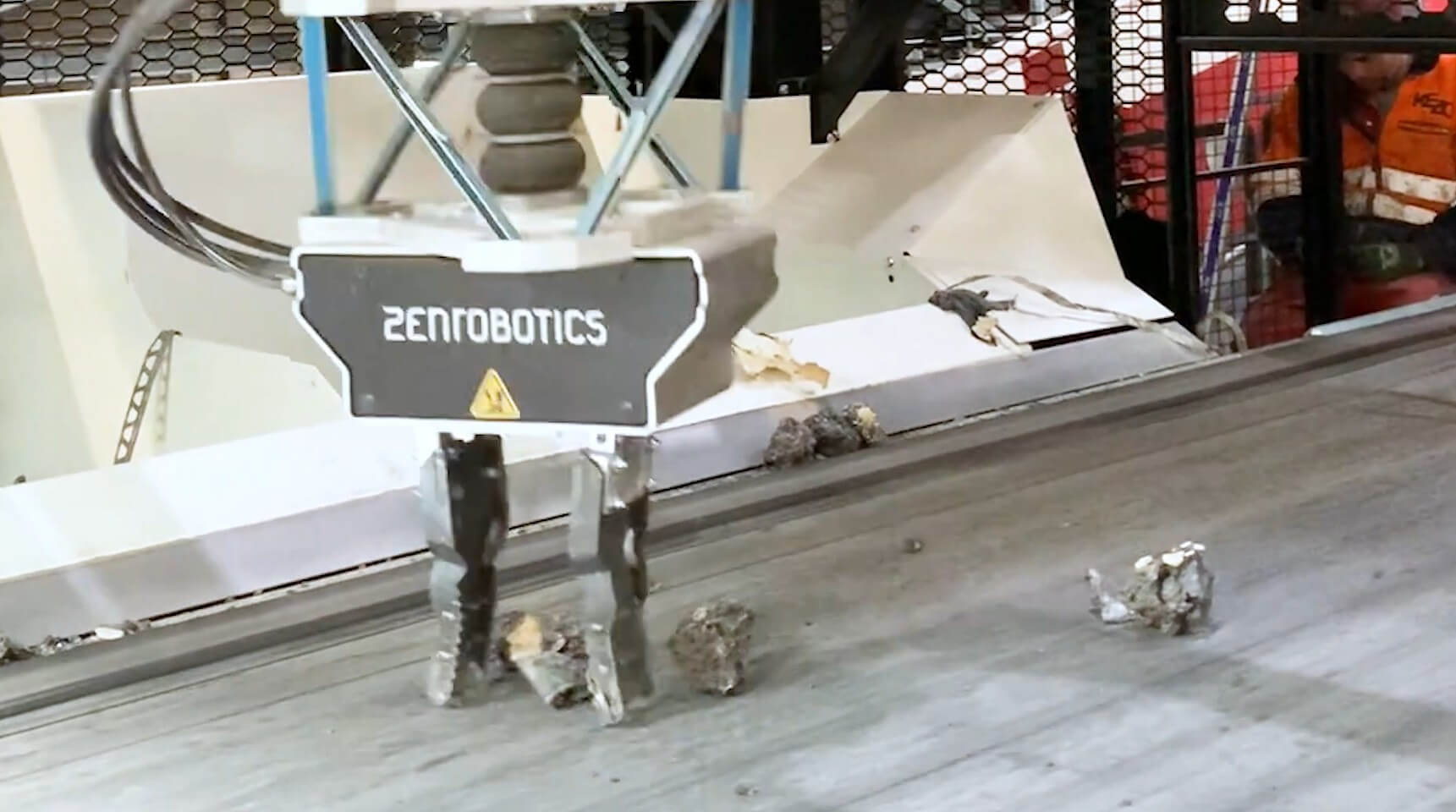

Efficient waste sorting at ZAV Recycling AG

A state-of-the-art sorting plant was built for ZAV Recycling AG in Hinwil with the aim of making slag sorting more efficient, precise and sustainable. The focus was on integrating the AI-supported ZEN sorting robot, which was specially developed to separate metallic recyclables from waste incineration plant ash.

Genossenschaft Migros Luzern

We were commissioned by the Migros Lucerne cooperative to comprehensively renovate and expand the existing container conveyor system.

Holcim (Switzerland) AG, Brunnen plant

Modernisation & integration of new components – Frei Fördertechnik AG was commissioned with the planning, implementation, installation and commissioning of the truck loading and material feeding systems, as well as the dismantling of the old systems.

Grisoni Zaugg SA

Maximising flexibility in material processing. The modernisation and expansion of the processing plant enable more difficult clay materials to be processed. Two modern turbo washers, four belt conveyors and improved sand processing now make this plant state-of-the-art in terms of efficiency, safety and operation.

Amrein AG, new recycling plant

Successful implementation of a pioneering flagship project: construction of a state-of-the-art recycling plant for Amrein AG in Rickenbach (LU).