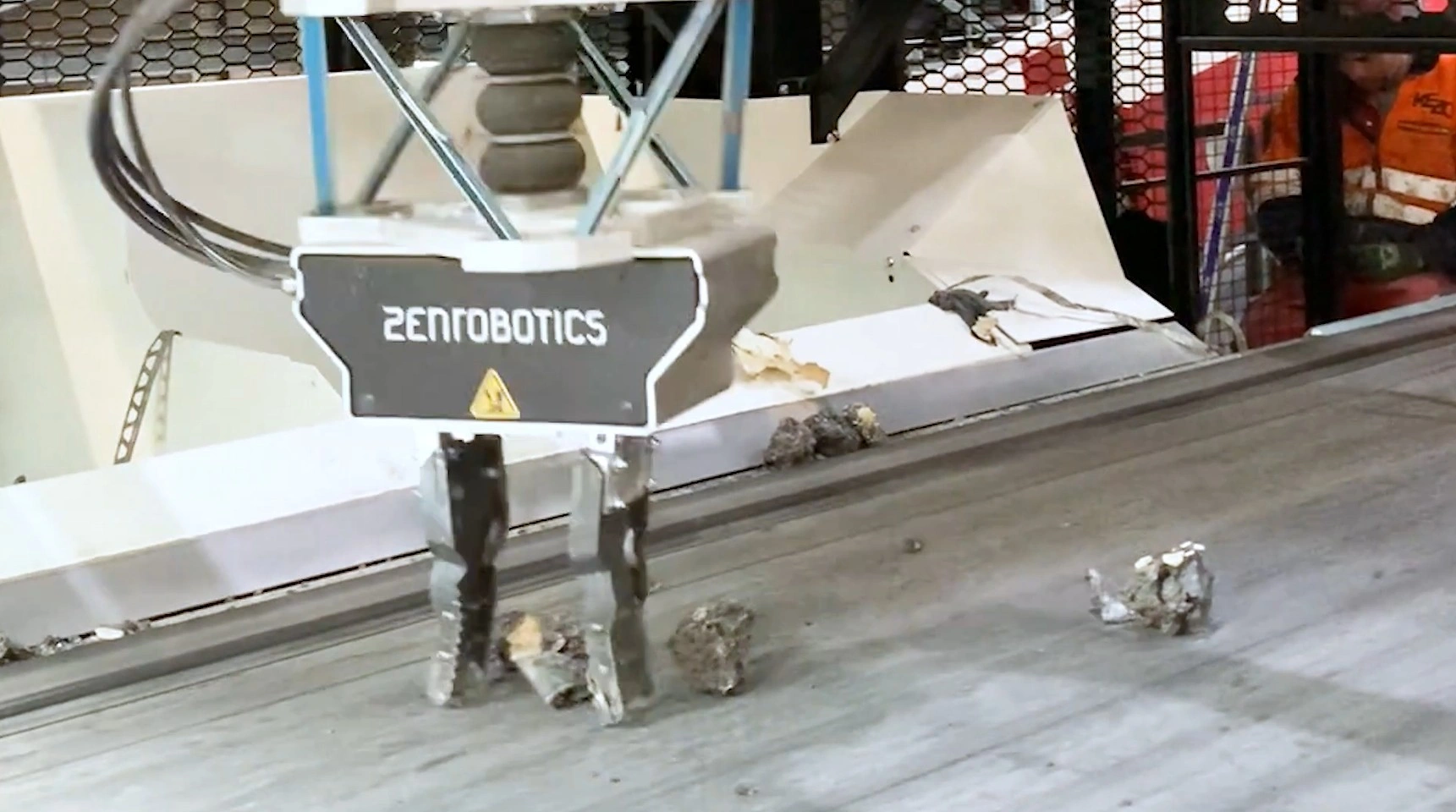

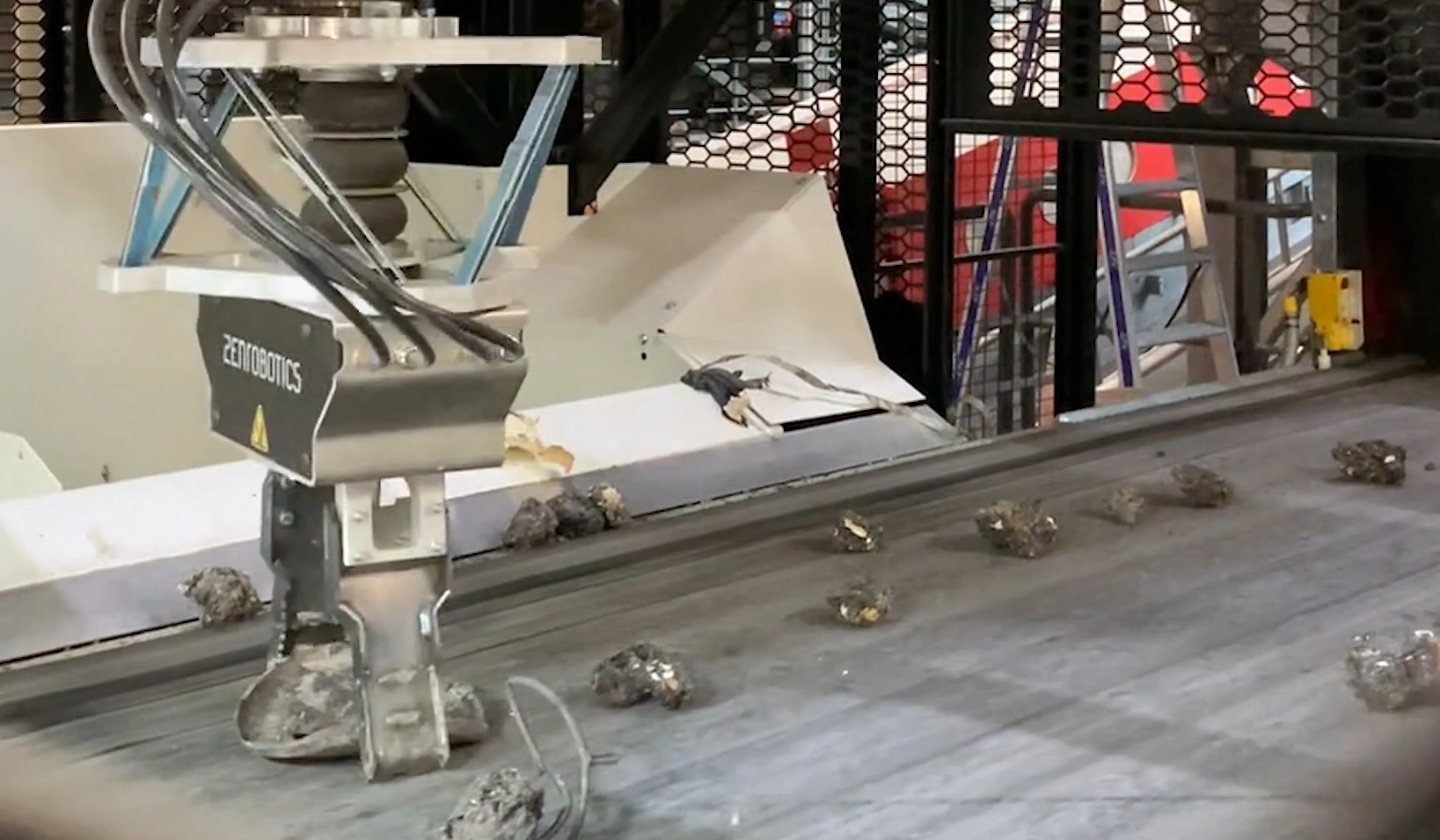

A state-of-the-art sorting plant was built for ZAV Recycling AG in Hinwil with the aim of making slag sorting more efficient, precise and sustainable. The focus was on integrating the AI-supported ZEN sorting robot, which was specially developed to separate metallic recyclables from waste incineration plant ash.

- Client/builder

- ZAV Recycling AG

- Location

- Hinwil

- Project

- Automated sorting plant for waste incineration plant ash

- Year of construction

- 2025

- Sector

- Building materials (Non-metallic minerals / Recycling)

Project

In close cooperation with qualified project partners, a technically sophisticated overall system consisting of the world's strongest heavy picker, innovative conveyor technology and new drop chutes with slides was successfully implemented.

The automation of the sorting process not only increases resource efficiency but also significantly improves the profitability of recyclable material recovery – a groundbreaking step towards a circular economy and sustainability.

Technical implementation by Frei Fördertechnik:

With extensive experience in conveyor and environmental technology, Frei Fördertechnik AG took on the technical implementation of the new sorting line – from design to commissioning. The focus was on a robust, low-maintenance and intelligent solution for demanding waste separation on an industrial scale.

Thanks to the use of state-of-the-art robotics, intelligent conveyor technology and precise control systems, a new benchmark in waste recycling has been set. With this project, Frei Fördertechnik AG has made an important contribution to the future of sustainable recyclable material recovery.

Scope of services in detail:

- Delivery and integration of the ZEN – Heavy Picker sorting robot

- Implementation of customised conveyor systems for material feed and removal

- Design and installation of new discharge chutes with pneumatic slides

- Integration of control technology into existing control systems in close cooperation with the customer

- Ensuring a smooth material flow, taking into account demanding conveyor goods (waste incineration plant ash)

- Planning and implementation of a compact, maintenance-friendly plant design

Special features:

- Use of the world's most powerful sorting robot for heavy metals

- AI-supported sensor technology for precise separation of different metallic recyclables

- Unmanned operation to reduce personnel deployment and increase occupational safety

- Integration into existing infrastructure during ongoing operation

- High plant availability and easy maintenance

- Contribution to the resource-saving recovery of metals from waste materials

Contact person