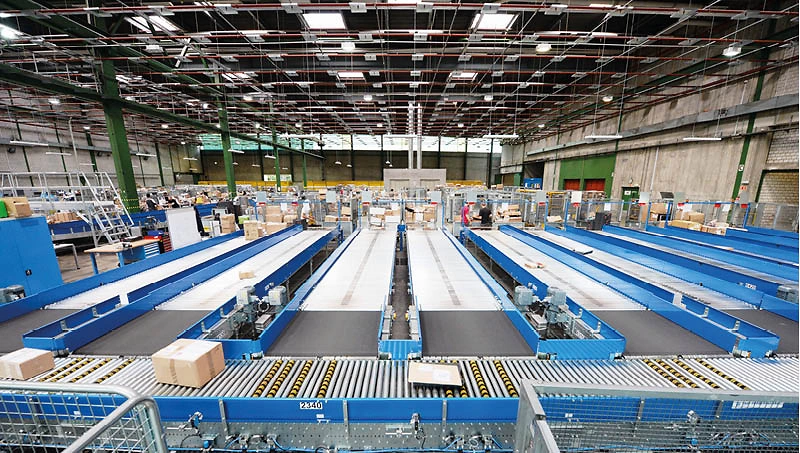

The conveyor system is used for handling during customs processing and for pre-sorting packages. The work process was ergonomically designed and partially automated. At the same time, the quality of the processing was increased and the process has become more cost-efficient.

- Client/builder

- Post CH AG

- Location

- Urdorf

- Project

- Conveyor system "Progress SPI"

- Year of construction

- 2013

- Sector

- Non-Food

Project

Frei Fördertechnik AG took on this contract as general contractor. Project planning was closely followed and different versions (with and without sorter, fully and semi-automatic) were tested. The system was created as a complete system with control unit and control computer and with an interface to the customs computer of Swiss Post. Today, the packages are processed based on customs bar codes. Where necessary, the weight is entered and applied to the order. With the customs software of Swiss Post, the data are then adjusted and replaced.

Special features

- Challenging merging of manual and automated processes.

- Critical requirements due to different package sizes; limited possibilities and high demands on flexibility in terms of the varying outputs throughout the day, depending on the area

- Complex conveyor system for weight control and sorting of large and small packages

Technical data

- Conveyed goods

- International parcels

- Size

- min. 100 x 100 x 10 mm, max. 1050 x 630 x 630 mm

- Weight

- 0.1 – 33 kg

- Speed

- 0.2 – 1.5 m/s

- Sorting capacity

- 2400 units/h

- Control unit

- Siemens S7300

Contact person

Head of Project Sales Intralogistics, Technical Consulting and Sales

+41 31 720 56 23

k.hulliger@ffag.ch