Mondelez Schweiz Production GmbH produces Toblerone chocolate bars in a wide range of shapes and sizes The system transports packaged products via conveyor technology to the moulding system on the one hand, and transports the packaged products away to various secondary packaging systems on the other.

- Client/builder

- Mondelez Schweiz Production GmbH

- Location

- Bern

- Project

- Conveyor system for "Mini" and "Tiny" Toblerone chocolate bars

- Year of construction

- 2005

- Sector

- Food

Project

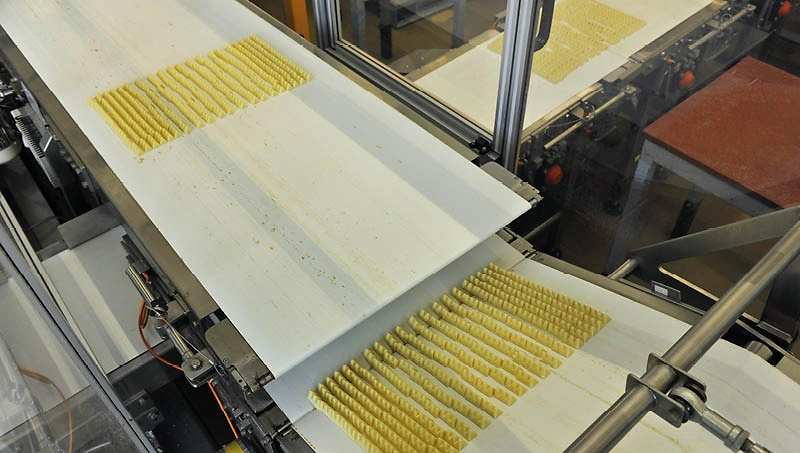

As general contractor, Frei Fördertechnik AG implemented this challenging project in several stages. The products are taken individually or on boards from the moulding system and cycled to an even speed. Four tubular bag machines are serviced by four depositing belts. Deficient, incorrectly packaged products (equipment malfunction) are stacked at the end of the line on boards. The products are then transferred to a storage unit, from which they are fed to the secondary packaging area, as well as to octabins (pallet frames).

Special features

- Uniform speed according to a sine curve

- Accurate transitions and quiet transport for very small items is required

- Reliable operation due to online connection (no accumulation at any time)

- Servo-controlled product board dispenser synchronised with the product.

Technical data

- Conveyed goods

- Plates, 344 x 530 mm

- Capacity

- 32 boards/min

- Conveyed goods

- Mini, 24 x 49 mm, Tiny, 18 x 36 mm

- Machinery

- 4 packaging lines, 2 octabin filling stations, stacker trays, 1 feed line, 1 storage connection

Contact person

Head of Project Sales Intralogistics, Technical Consulting and Sales

+41 31 720 56 23

k.hulliger@ffag.ch