The balancing act between excavation and RC material processing - With H2M, Frei Fördertechnik AG has created a system that is capable of efficiently processing both excavated and RC material. The RC material is freed from impurities by means of a kidney function. The processed end products are fed directly to the concrete centre's silo system.

- Client/builder

- H2M Exploitation SA

- Location

- Vufflens-la-Ville

- Project

- New washing plant

- Year of construction

- 2022

- Sector

- Building materials (Non-metallic minerals / Recycling)

Project

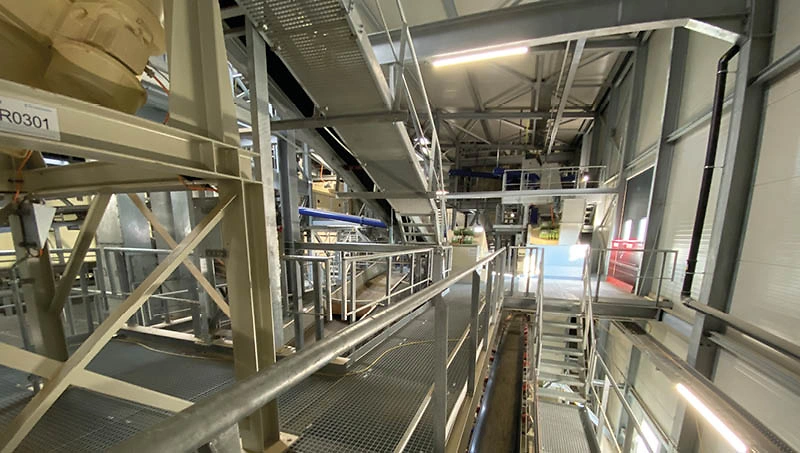

In Vufflens-la-Ville, Frei Fördertechnik AG realised a washing and sorting plant for H2M Exploitation SA for the processing of excavated material from deposits and excavated earth for recycling. The washing and sorting plant is located in the immediate vicinity of the new ECO-CIRCULAR concrete centre (BGO SA) and an aggregate receiving plant. These three plants will be able to work in synchronisation. This huge sorting platform from H2M is directly connected to the railway. By transporting the raw materials by train from the Délices gravel pit in Apples, the companies are acting as pioneers in the industry.

Special features

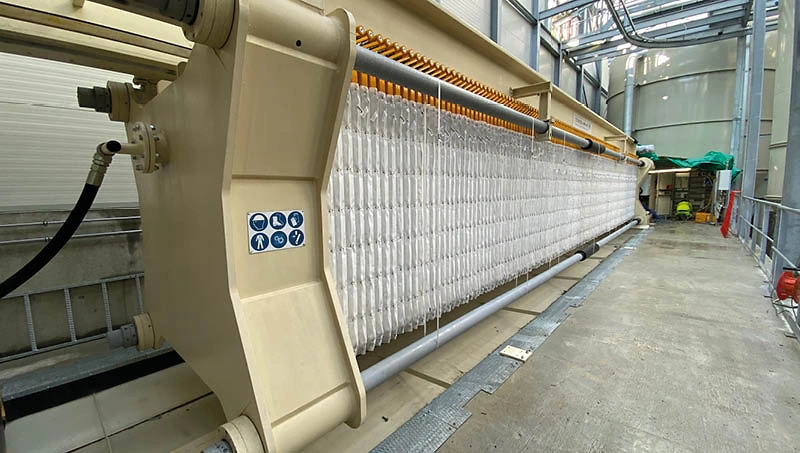

- Hydraulic angle adjustment of the sword wash

- Separation of non-ferrous material using an eddy current separator

- Sand processing with upflow classification and fine sand dosing

- Two wastewater treatment plants for the treatment of clean or contaminated sludge water

- Discharge line of 800 t/h towards the silo plant

Watch the video here.

Technical data

- Feed material

- 0-400 mm, pre-screening at 100 mm

- Plant feeding capacity

- 140 t/h

- Installed capacity

- 1095 kW

- End products

- 0/4, 4/8, 8/16, 16/32

- Installed machines (selection)

- Sand processing by means of upflow classification, heavy-duty washing, sludge and water treatment, intermediate silos, ne separator and setting machine

Contact person