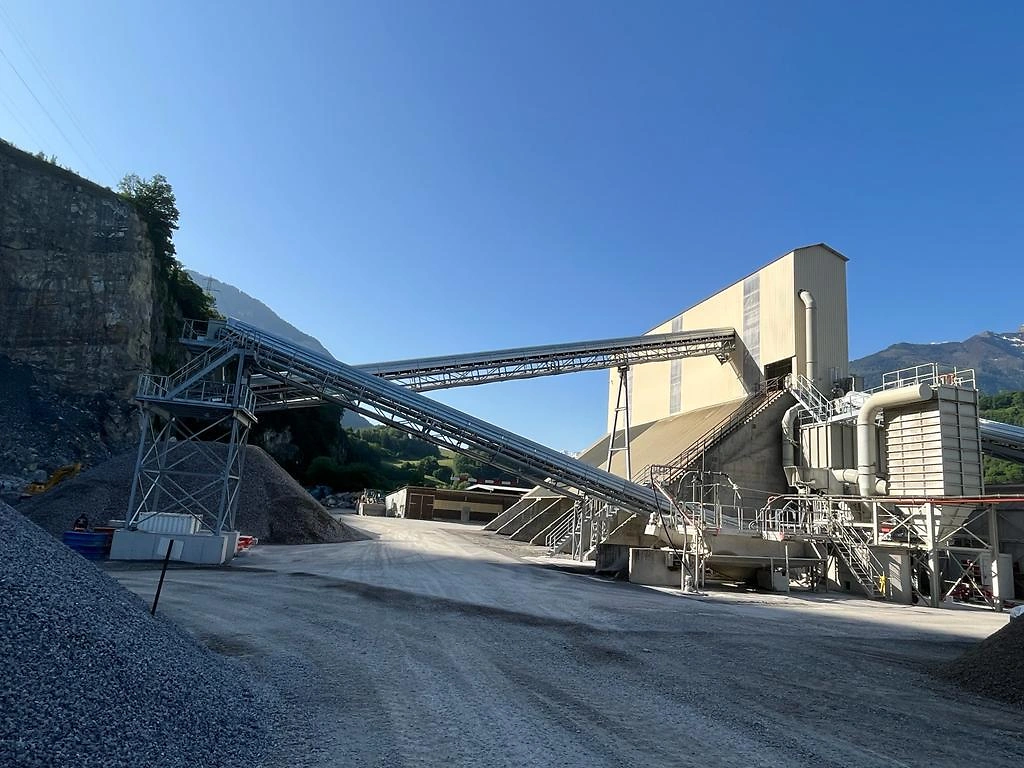

Maximising productivity - The modernisation of the grit processing system has maximised productivity at the gravel plant. Environmental efficiency has been increased and the plant is state of the art in terms of safety and operation.

- Client/builder

- Carrière de Sous-Vent

- Location

- Bex

- Project

- Modernisation of grit processing

- Year of construction

- 2022

- Sector

- Building materials (Non-metallic minerals / Recycling)

Project

The Carrière de Sous-Vent has been in operation since 1857. It produces more than 100,000 tonnes of gravel per year. The quality of the gravel is constantly monitored. The plant is utilised with care and absolute respect for the environment and supplies high-quality materials.

Frei Fördertechnik AG was commissioned to modernise the gravel processing plant. The old gravel plant was partially dismantled. The old conveyor belts and screening machines were lifted out of the building. New steel platforms were installed and the new machines, such as a new impact crusher, conveyor technology and dedusting system, were brought in and put into operation.

Following the conversion of the plant, productivity was maximised, environmental efficiency increased and the plant is now state of the art in terms of safety and operation.

Special features

- New steel platforms in existing steel structure

- Completely new façade and roof

Technical data

- Feed material

- Chippings

- Plant loading performance

- 130 t/h

- Loading capacity

- 300 t/h

- Installed capacity

- 252 kW

- Final products

- 0/4, 4/8, 8/11, 11/16, 8/16, 16/22

- Installed machines (selection)

- Impact crusher, conveyor technology, dedusting plant, steel construction

Contact person