Corrugated edge conveyor system to replace the old chain conveyor system - Due to high maintenance costs, the old chain conveyor system was replaced. Frei Fördertechnik AG provides clear arguments for the use of a new wave edge conveyor belt to the benefit of the customer.

- Client/builder

- Schweizer Zucker AG

- Location

- Frauenfeld

- Project

- System for loading the coke and lime silos

- Year of construction

- 2011

- Sector

- Industry

Project

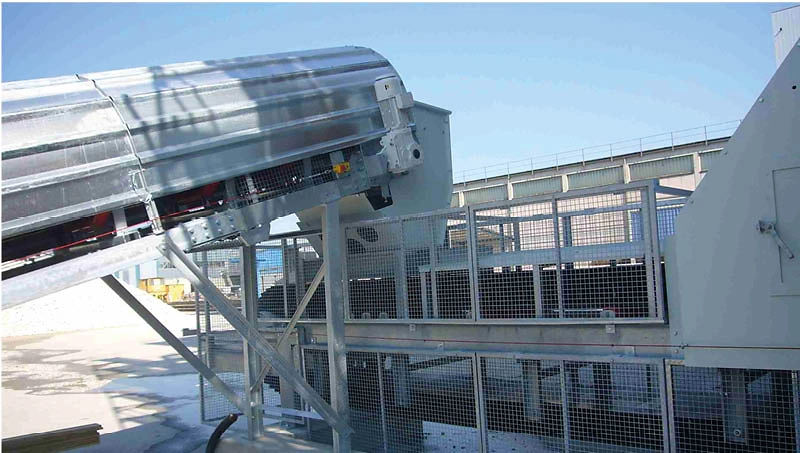

Frei Fördertechnik AG presented a new concept, which had clear advantages in terms of the routes of the dumpers as well as the silo capacity. To date, the limestone kiln was fed with coke and limestone via a silo. Since the silos and the chain conveyor no longer corresponded to the state of the art, they had to be replaced. The silo elevation made of was put on the existing concrete head of the silos, and the feed station was repositioned. The corrugated edge conveyor is fed via a silo with a loading height of three metres and a batch feed tray. With a connecting belt that overcomes the height difference to the corrugated edge conveyor, the limestone or the coke is transferred to the vertical conveyor. At the discharge station of the corrugated edge belt, each silo is fed from a reversing conveyor.

Special features

The system solution of Frei Fördertechnik AG made for a considerable increase of the silo capacity.

Technical data

- Feed material

- Limestone, coke

- Feed capacity

- 80 m3/h = 120 t/h

- Feed sizes

- 0 –150 mm

- Vibrating chute

- belt width controlled by frequency converter

- Corrugated edge conveyor

- 800 mm

- Corrugated edge conveyor

- 18.5 kW

- Distance between axles, corrugated edge conveyor

- 26 m

- Gradient, corrugated edge conveyor:

- 16 m mit 90° gradient

- Corrugated edge belts

- Type Flexowell

- Corrugated edge heigh

- 240 mm

- Cleats

- TC 220, distance 250 mm

Contact person

Member of the Executive Board, Head of Service

+41 31 720 56 44

f.rothenbuehler@ffag.ch