Benutzerfreundlich, robust und langlebig

Aarekies Aarau-Olten AG

The gravel and concrete producer belonging to Jura Holding has heralded a new era in the treatment of aggregates with this new gravel plant in Buchs. The state-of-the-art plant makes Aarekies-Olten AG the leading supplier of sand and gravel in the Aarau region.

VITO Recycling AG, Soil washing plant

Processing plant sets standards for material recycling - Contaminated mineral construction waste and contaminated soil materials are processed in the soil washing plant. In the process, a maximum number of impurities can be separated.

ARGE GRIMSEL, Gerstenegg treatment plant

Temporary plant at 1,710 metres above sea level. Due to the construction of the new ‘Spitallamm’ replacement dam by Kraftwerke Oberhasli AG (KWO), Frei Fördertechnik AG built a treatment plant on the Gerstenegg Grimsel Pass.

BRT Baustoff Recycling Thurgau AG

Processing plant closes the cycles in concrete production. BRT AG's aim was to close the material cycles in the regional construction sector. Using state-of-the-art technology, mineral materials are processed and the reusable components are recovered as high-quality building materials.

RCO Recycling Center Ostschweiz AG

High-quality building materials thanks to state-of-the-art building materials recycling plant - Frei Fördertechnik AG was responsible for the planning, engineering in close cooperation with RCO, fabrication, assembly, E-MSRL control and commissioning of the building materials recycling plant as a complete turnkey system.

BM Betonwerk Malters AG

Conveyor technology for perfect stockpiling - Frei Fördertechnik AG was commissioned with the planning, realisation, assembly and commissioning of the new covered component storage facility. The system is used to store the processed excavated, concrete and mixed demolition components.

Carrière de Sous-Vent

Maximising productivity - The modernisation of the grit processing system has maximised productivity at the gravel plant. Environmental efficiency has been increased and the plant is state of the art in terms of safety and operation.

Conforti SA

State-of-the-art technology - Following this conversion of the plant, the productivity of Carrière de l'Aboyeu has been maximised and fully complies with the latest state of the art in terms of safety and operation.

H2M Exploitation SA

The balancing act between excavation and RC material processing - With H2M, Frei Fördertechnik AG has created a system that is capable of efficiently processing both excavated and RC material. The RC material is freed from impurities by means of a kidney function. The processed end products are fed directly to the concrete centre's silo system.

Makies AG

16 tonnes for the perfect wash - After 40 years of reliable operation at Makies AG in Gettnau, the time has come to replace the entire washing drum. Frei Fördertechnik AG was commissioned with the replacement.

Kieswerk Oldis AG

The path to the circular economy - The extensive new construction of the processing plant enables primary gravel, recycled and excavated materials to be processed and returned to the material cycle as high-quality construction materials.

Surer UPREC AG

Are you still dumping or already washing? Mineral construction waste is processed and classified in our in-house recycling centre. The centre produces high-quality recycled building materials that meet the highest ecological and structural requirements.

Tägerhard Kies AG

Perfect replacement despite structural challenges - The special challenges of the structural conditions and the actual installation of the machines in confined spaces were realised without any problems thanks to our customised solution.

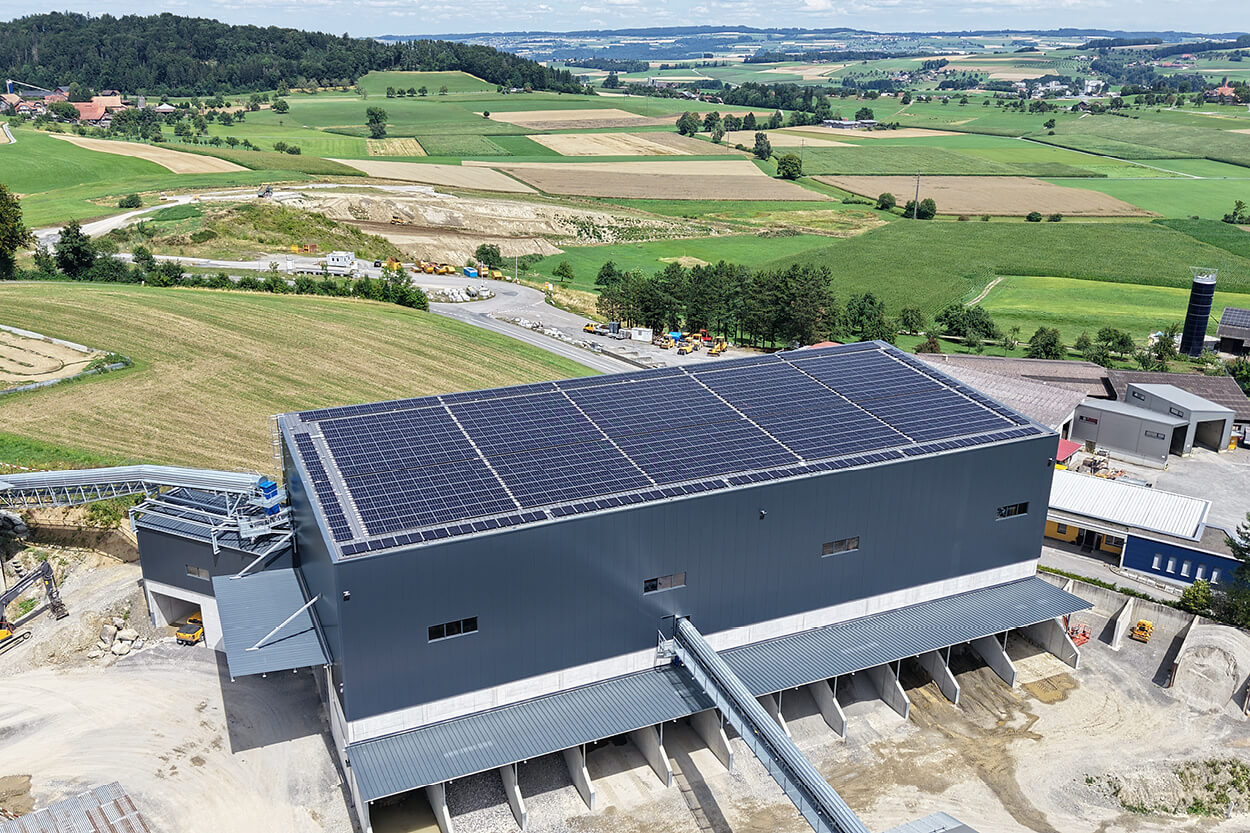

Eberhard Bau AG, EbiMIK

New construction of the EbiMIK LOS 01 Oberglatt building material mixing and demolition processing plant for sustainable ‘urban mining’ with a closed cycle. State-of-the-art crushing and screening plants with a sophisticated robotic sorting line form the first stage of a highly modern building material recycling plant.

Messerli Kieswerk AG, Oberwangen

After 40 years of planning and only 16 months' construction time, the cutting-edge gravel and concrete plant of Messerli Kieswerk AG in Oberwangen was inaugurated in 2013. The new plant replaces two old gravel plants and offers the separate feeding of gravel and moraine material as well as their flawless processing.

Aarekies-Olten AG

The gravel and concrete producer belonging to Jura Holding has heralded a new era in the treatment of aggregates with this new gravel plant in Buchs. The state-of-the-art plant makes Aarekies-Olten AG the leading supplier of sand and gravel in the Aarau region.

Baustoffzentrum Olten/Zofingen BOZ

Optimal connection with 1.2 km of conveyor technology – The newly implemented conveyor technology connects the two plants in Gunzgen and Boningen. This eliminates the need for truck journeys on the road network.

Vigier Beton Mittelland AG

For modern gravel processing. Modern, robust construction adapted to the requirements of gravel processing technology. From engineering to assembly and commissioning – we supplied everything from a single source.

Birchmeier Kies + Deponie AG

Birchmeier Kies + Beton AG has been successfully operating a gravel and concrete plant in Döttingen since October 2016. The expansion in the Hard-Härdli area in Klingnau will secure the regional supply of high-quality gravel in the long term.

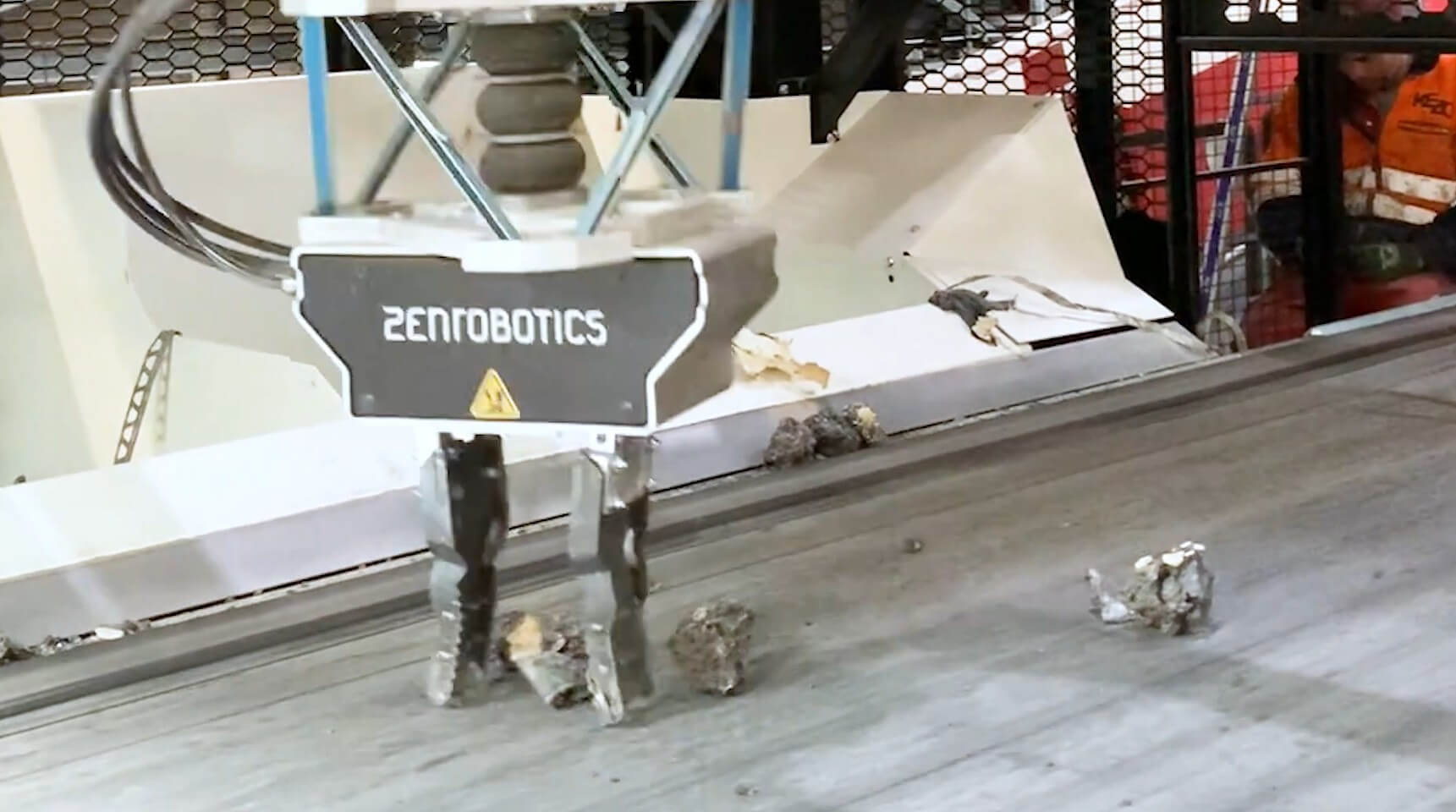

Efficient waste sorting at ZAV Recycling AG

A state-of-the-art sorting plant was built for ZAV Recycling AG in Hinwil with the aim of making slag sorting more efficient, precise and sustainable. The focus was on integrating the AI-supported ZEN sorting robot, which was specially developed to separate metallic recyclables from waste incineration plant ash.

Holcim (Switzerland) AG, Brunnen plant

Modernisation & integration of new components – Frei Fördertechnik AG was commissioned with the planning, implementation, installation and commissioning of the truck loading and material feeding systems, as well as the dismantling of the old systems.

Grisoni Zaugg SA

Maximising flexibility in material processing. The modernisation and expansion of the processing plant enable more difficult clay materials to be processed. Two modern turbo washers, four belt conveyors and improved sand processing now make this plant state-of-the-art in terms of efficiency, safety and operation.

Amrein AG, new recycling plant

Successful implementation of a pioneering flagship project: construction of a state-of-the-art recycling plant for Amrein AG in Rickenbach (LU).