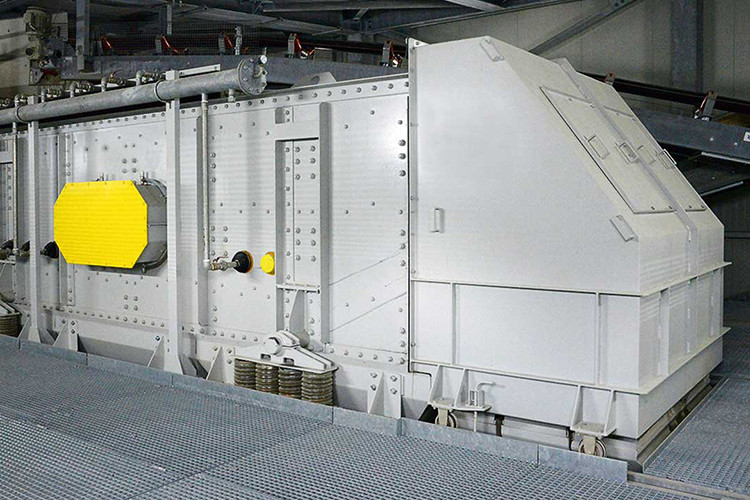

Screening machine/flip-flow screen

A screening machine is used to grade the bulk material according to desired particle sizes. In order to achieve a high level of screening quality, we pay special attention to the correct dimensioning of the screening machine, screen length and the material to be screened.

The various types of screening machine are fundamentally different in their drive system and the mode of operation that depends on it:

- circular vibratory screening machine (12-30° inclined/load dependent)

- elliptic screening machine (horizontal installation/load dependent)

- linear screening machine (without tilt/usually depending on load)

- eccentric screening machine (horizontal or inclined installation/load-independent)

<div/>

Flip-flow screens are ideal for the sizing of feed material that is difficult to filter. Through different types and designs of the machine and the screen mats, all circumstances can be covered. All types follow the basic principle of the trampoline-like movement of individual polyurethane screen mats, from the relaxed to the taut to the highly stretched state. The result is an optimal operational reliability. Problems caused by clogging and terminal grain can practically be ruled out.

<div/>

Scope of application

- Waste incineration systems

- Sorting systems

- Glass recycling plants

- Landfills

- General sizing technology

<div/>

Accessories

- Screening surfaces

- Gear motor

- Damping elements

- Feed/discharge hopper