(copy 2)

-

Intralogistics

Intralogistics

Thermal inline testing for heat-sealed packaging

-

Company

Company

Change to the Board of Directors from 01 April 2024

-

Recycling

Recycling

IFAT 2024, Munich - The world's leading trade fair for environmental technologies

-

Recycling

Recycling

Handover of keys for BRT Baustoff Recycling Thurgau AG

-

Industry

Industry

Silo extension and new lorry loading for Peter Holzbau AG

-

Company

Company

The FFAG team wishes you a Merry Christmas and a successful New Year!

Company

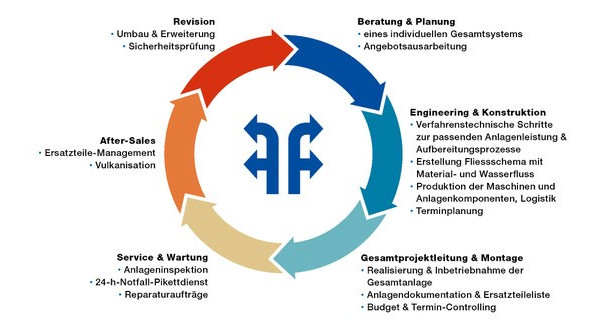

Company profile

Frei Fördertechnik AG, a traditional family company, has been active in materials handling for over 55 years. Swiss quality, innovation, high productivity and safety are distinguishing features of the Frei brand. Our extensive experience and professional expertise have a direct impact on the success of your project.

With us, you get tailor-made solutions for any type of material to be conveyed. As a general contractor, we create complete systems – from planning to manufacture and commissioning. As an ISO certified company, Frei relies on innovative in-house developments that pass the test with flying colours as quality products in daily operation.

Our strategic business areas are:

► Brochure company portrait (German)

► ISO 9001 Certificate (German)

Substantial advantages

- Consultancy in field service

- Planning and design department

- Separate manufacturing of steel and stainless steel products

- Sand blasting equipment

- Paint shop

- Installation and vulcanisation

Expertise and excellence

- Responsible consultancy

- Cost-conscious planning

- Project consultancy by engineers and designers with longstanding experience

- Production at our own factory in Rubigen

- Installation by trained teams Service and maintenance by qualified personnel

FREI FÖRDERTECHNIK AG

YOUR GENERAL CONTRACTOR

Tailor-made solutions, experience, expertise and meticulous planning are the cornerstones for the success of the projects.

An accurate flow chart is drawn up for the planning of each system. In this step, all the customer's specifications are integrated, and machines and components are combined accordingly.

We take on projects as a general contractor and are therefore responsible for all concerns with respect to the client. This has great advantages for both sides. The customer has a single contact partner for everything: we are responsible for ensuring that everything runs smoothly, from project planning to start of production and even after commissioning.

We also transport milestones

Our history

Timeline

2024 | New construction of the Monthey service centre: |

2023 | ISO 9001:2015 recertification |

2022 | Handing Over Management on 1 June 2022 of Collin Frei to Jan Blatter and Patrick Zimmermann |

2021 | Opening of the service location Eastern Switzerland in Wetzikon ZH |

2017 | 50 years jubilee |

2016 | Takeover of the stationary treatment of non-metallic minerals of the |

2011 | Opening of branch offices in West- and Eastern Switzerland |

2010 | New construction of West factory hall, 1,035 m2 |

2009 | Expansion, new offices, 2nd floor, 425 m2 |

2006 | Expansion, new offices, 2nd floor, 400 m2 |

2001 | Dedication of new manufacturing building, 1,000 m2 and new office building, 300 m2 |

1998 | Introduction of quality management in accordance with ISO 9001 |

1992 | Dedication of new manufacturing building, establishment of "stainless" department |

1981 | Building-up of the sole agency for Transnorm for Switzerland |

1978 | Construction of the first proprietary premises in Rubigen |

1974 | Takeover of the commercial agency for ISENMANN Siebe GmbH, Karlsruhe |

1967 | Company founded by Ernst Frei |

Legal form

Public limited company

Owners

Frei family

(Christian Frei, Collin Frei)

Management Board

Jan Blatter (Co-CEO)

Patrick Zimmermann (Co-CEO)

Fritz Rothenbühler

Marc Geissbühler

Andreas Lauber

Michael Hangartner

Subsidiary

VTS Verschleisstechnik AG

Since 1 June 2016, VTS Verschleisstechnik AG has operated as a fully owned subsidiary of Frei Fördertechnik AG. Headquarters remain in Schaffhausen. VTS Verschleisstechnik AG also keeps its tried-and-tested team.

VTS Verschleisstechnik AG is your ideal partner for wear parts of every kind for a wide range of stationary and mobile systems. The large warehouse is tailored to your needs and managed accordingly. You’ll therefore receive your wear parts in no time at all.

As a service and consultancy company, VTS Verschleisstechnik AG stands by you in every situation. The technicians develop special forms for you to increase the efficiency of your machine. We also advise you on problems such as changes in wear behaviour and the acquisition of new machinery.

Explore the website at: www.vtsag.ch

Our

mission statement

Our guiding principles

Core values such as appreciation, honesty, innovation and reliability carry us forward to success. Appreciation is the guiding principle for our way of thinking and acting.

Our behaviour

We always act in a customer-focused, reliable, fair and honest way towards customers, suppliers, employees and partners. We stand for the highest level of conscientiousness, flexibility and innovative spirit.

Our employees

We motivate our employees by activating their own spirit of initiative, trusting them, giving them responsibility and acknowledging extraordinary performance. We maintain a good, friendly working environment.

Our promise

We set new quality standards in all our activities. Excellent customer support, a customer-orientated warehouse as well as top-notch in-house production set us apart. Best Swiss quality is our ultimate goal, one that we pursue on every level every day.

Our

mission

Frei Fördertechnik fosters a corporate culture in which striving for excellence, personal responsibility, identification with the company and social awareness can thrive and grow. Collaboration is characterised by a motivating team spirit, openness and fairness. We see suppliers as partners, since they make a significant contribution to our range of offers.

We also assume responsibility for the protection of the environment as well as the health and safety of our employees by acting accordingly. We ensure the development and independence of our family business through appropriate and fair profits, a substantial part of which are reinvested into the company's development.

Ideal start to professional life

Open apprenticeship positions 2025/2026

Apply now - We are offering exciting apprenticeships from summer 2025/2026!

In our company, a total of 9 to 11 apprentices are trained at the same time. We offer motivated young people practical and varied vocational training in an exciting and lively environment. Modern work equipment and a pleasant working atmosphere promote personal and professional development.

An apprenticeship at Frei Fördertechnik AG is exciting and varied - because we are a dynamic and modern company.

We offer apprenticeships in the following professions.

- Commercial clerk EFZ 2025/2026

- EFZ logistics technician 2026

- EFZ design engineer 2025/2026

- Plant and apparatus engineer EFZ 2025/2026

Trial apprenticeships, internships and training are all possible: because promoting young talent is close to our hearts.

Do you have any questions or are you interested in a trial apprenticeship? We are here for you and will be happy to answer your questions.

Brigitte Marmet, Human Resources, is at your disposal.

Direct phone 031 720 56 65 / E-mail b.marmet@ffag.ch

Konstrukteur/In EFZ

Interessierst du dich für Technik und erarbeitest du gerne kreative Lösungen? Wie wäre es mit einer Ausbildung als Konstrukteur/In?

Als Konstrukteurin EFZ oder Konstrukteur EFZ entwickelst Du mit 3D-Software Einzelteile und Baugruppen von Maschinen, Apparaten oder Alltagsprodukten.

Du führst ganze Projekte oder Teile von Projekten durch. Auch das Bestellen von Einkaufsteilen (z.B. Elektromotoren, Ventile, Zahnräder etc.), das Erstellen von Stücklisten oder von Bedienungsanleitungen gehört zum Aufgabengebiet des Konstrukteurs.

Dauer: 4 Jahre, davon 1 bis 2 Tage pro Woche Berufsschule

Anforderungen: Grosses Interesse an technischen Zusammenhängen, Freude an Mathematik, Physik und Mechanik, Konzentrationsfähigkeit; Organisationstalent; Strukturiertes Arbeiten.

Weiterbildung: Nachdem Du die Lehre als Konstrukteur/in EFZ abgeschlossen hast, kannst Du ich in die verschiedensten Richtungen weiterbilden. Du kannst dich an einer höheren Fachschule zum Techniker HF oder an einer Fachhochschule FH zum Ingenieur ausbilden lassen. Zudem gibt es eine Fülle von Seminaren und Weiterbildungskursen.

► Flyer Konstrukteur EFZ bei der Frei Fördertechnik AG

► Hier geht's zum Video Konstrukteur bei der Frei Fördertechnik AG

Anlagen- und Apparatebauer/In

Hast du Interesse an Maschinenarbeit und Metallverarbeitung? Wie wäre es mit einer Ausbildung als Anlagen- und Apparatebauer/In?

Die Welt des Anlagen- und Apparatebauers oder der Anlagen- und Apparatebauerin sind Bleche, Profile und Rohre aus mehrheitlich metallischen Werkstoffen.

Willkommen im Beruf, der in jeder Beziehung in Bewegung ist. Der Anlagen- und Apparatebauer baut anhand von Bauplänen oder Modellen Apparate, Maschinen und Anlagen wie z.B Förderanlagen, Luftseilbahnen, Aufzüge, Bahnen, Untergrundbahnen, Druckmaschinen, Medizinalanlagen und Werkzeugmaschinen und führt die damit verbundenen Montage- und Inbetriebsetzungsarbeiten aus. Er oder sie repariert und ersetzt auch schadhafte Komponenten.

Dauer: 4 Jahre, davon 1 bis 2 Tage pro Woche in der Berufsschule

Anforderungen: Handwerkliches Geschick, technisches Verständnis, Gutes räumliches Vorstellungsvermögen, körperliche Beweglichkeit, robuste Gesundheit, kräftige Konstitution und keine Allergien gegen Metalle.

Weiterbildung: Diverse Berufsprüfungen mit eidg. Fachausweise: Schweissfachmann/frau, Prozessfachmann/frau, Fertigungsfachmann/frau, Instandhaltungsfachmann/frau. Höhere Fachprüfung mit eidg. Diplom als Industriemeister/in im Maschinen- und Apparatebau, Techniker/in HF in Maschinenbau, Betriebstechnik, Produktionstechnik. Bachelor FH in Chemie, Maschinentechnik, Systemtechnik

► Flyer Anlagen- und Apparatebauer bei der Frei Fördertechnik AG

► Hier geht's zum Video Anlagen- und Apparatebauer bei der Frei Fördertechnik AG

Kauffrau/Kaufmann EFZ

Interessierst du dich für wirtschaftliche Zusammenhänge und organisierst du gerne? Wie wäre es mit einer Ausbildung als Kauffrau/mann?

Als Kauffrau/Kaufmann übernimmst du verschiedenartige Tätigkeiten, die sich in der Administration abspielen: Du schreibst Offerten und Rechnungen, korrespondierst per Brief und per E-Mail, berätst Kundinnen und Kunden im Geschäft oder am Telefon, hilfst in der Buchhaltung mit, betreust Dossiers oder organisierst Termine und Veranstaltungen.Wenn du gerne im Team und am Computer arbeitest, Freude am Kontakt mit Menschen hast, zuverlässig und selbstständig bist, dann ist Kauffrau/Kaufmann EFZ der richtige Beruf für dich.

Dauer: 3 Jahre, davon 1 bis 2 Tage pro Woche in der Berufsschule

Profile: B-Profil (Basis-Grundbildung), E-Profil (Erweiterte Grundbildung), E-Profil mit Berufsmaturität

Anforderungen: Kontaktfreudigkeit, Kundenorientiertheit, Lernfreude, Organisationstalent, rasche Auffassungsgabe, Selbstständigkeit, Sinn für Zahlen, Teamfähigkeit, Vernetztes Denken, Vorstellungsvermögen, gute sprachliche Ausdrucksfähigkeit, Fremdsprachen.

Weiterbildung: Im kaufmännischen Bereich steht gut ausgebildeten Berufsleuten eine Vielzahl von Funktionen und Berufsmöglichkeiten offen.

- Verschiedene Berufsprüfungen (eidgenössischer Fachausweis): Fachmann/-frau des Finanz- und Rechnungswesens, Marketingfachmann/-frau, HR-Fachmann/-frau, Direktionsassistent/in, Spezialist/in öffentlicher Verkehr, Treuhänder/in usw.

- Verschiedene höhere Fachprüfungen (eidgenössisches Diplom): Dipl. Experte/-in in Rechnungslegung und Controlling, dipl. Marketingleiter/in, dipl. Leiter/in Human Resources, dipl. Aussenhandelsleiter/in, dipl. Immobilien-Treuhänder/in.

- Höhere Fachschule für Wirtschaft (HF): Dipl. Betriebswirtschafter/in HF, dipl. Bankwirtschafter/in HF, dipl. Versicherungswirtschafter/in, dipl. Wirtschaftsinformatiker/in HF.

► Flyer Kauffrau-Kaufmann bei der Frei Fördertechnik AG

► Hier geht's zum Video Kauffrau/mann bei der Frei Fördertechnik AG

Logistiker/In EFZ

Hast du Freude an praktischer Arbeit und interessierst Du Dich für den Warentransport? Wie wäre es mit einer Ausbildung als Logistiker/In?

Der Beruf des Logistikers oder der Logistikerin ist ideal für Menschen, die gerne anpacken. Sie bewegen sich in Lagerräumen von Dienstleistungs-, Handels- oder Produktionsbetrieben, aber auch in Brief- und Paketzentren, in der Postzustellung, in Güterverteilzentren oder an Bahnhöfen und Terminals. Logistiker und Logistikerinnen garantieren eine hohe Qualität und Wirtschaftlichkeit der Arbeitsabläufe, lernen viele Abteilungen des Unternehmens kennen und haben regelmässig Kontakt mit verschiedensten Leuten.

Dauer: 3 Jahre, davon 1 Tag pro Woche in der Berufsschule

Anforderungen: Freude an praktischer Tätigkeit und am Kundenkontakt, Ordnungssinn, Merkfähigkeit, Teamfähigkeit, hohes Verantwortungsbewusstsein, Freude am Umgang mit Computer, Flexibilität, Selbständigkeit, technisches Verständnis, gute Konstitution.

Weiterbildung: Logistik-Sachbearbeiter/-in mit SVBL-Diplom, geeignet zur Vorbereitung auf Führungsaufgaben in der Logistik, als eigenständiger Abschluss oder Zwischenstufe zum/zur Logistiker/in mit eidg. Fachausweis.

Berufsprüfungen: Logistiker/-in Lager-, Distributions- oder Produktionslogistik; Logistikfachmann/-frau, Prozessfachmann/-frau, Zolldeklarant/-in, Fachmann/-frau internationale Spedition und Logisitk, Aussenhandelsfachmann/-frau oder Einkaufsfachmann/-frau mit eidg. Fachausweis.

Höhere Fachprüfung: Dipl. Logistiker/-in, dipl. Logistikleiter/-in, dipl. Betreibsleiter/-in Transport und Logistik, dipl. Aussenhandelsleiter, dipl. Supply Chain Manager/-in, dipl. Leiter/-in internationale Spedition und Logistik oder dipl. Einkaufsleiter/-in.

Höhere Fachschulen: Dipl. Techniker/in HF, Fachrichtung Unternehmensprozesse mit Vertiefung Logistik.

► Flyer Logistiker bei der Frei Fördertechnik AG

► Hier geht's zum Video Logistiker bei der Frei Fördertechnik AG

Committed to the future

Research and development

As a forward-looking company, we invest a great deal in research and development. In the Engineering Department, our employees work on new, improved products and technologies.

Technically and economically compelling solutions are realised in close cooperation with our customers. A lot of innovative products have evolved over the last few years and stood the test of daily use to the advantage of our clients.

Unsere

Kollaborationen und Verbände