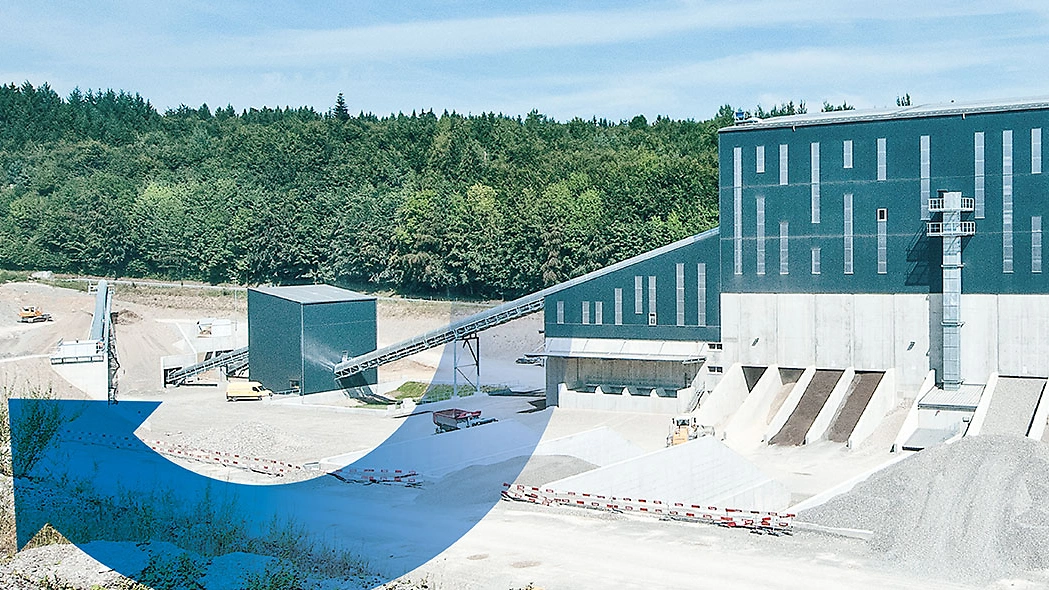

As a general contractor, we offer you comprehensive, individually adapted total solutions for every type of conveyed goods. From the initial consultation and detailed planning to the production and commissioning of the complete systems, you receive everything from a single source.

We accompany you every step of the way.