- Home page

- Building materials product range

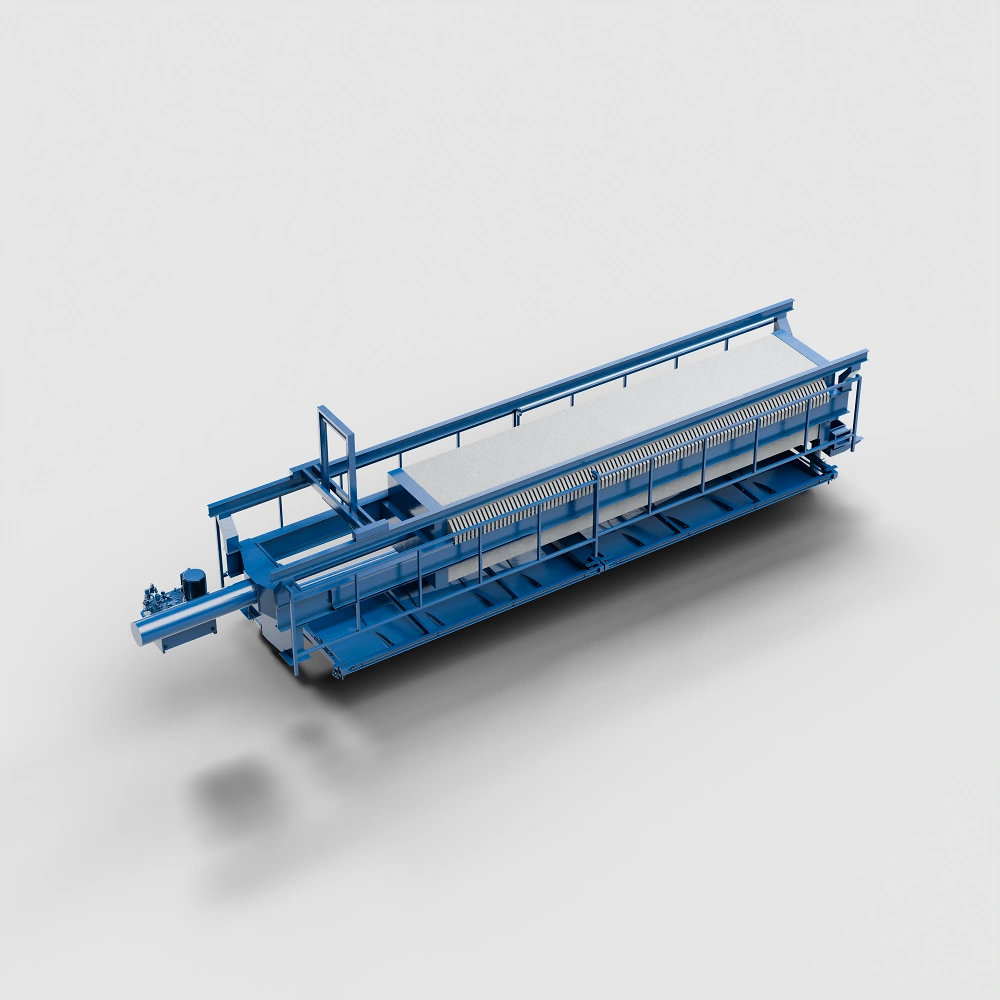

- Cellular filter press

Cellular filter press

Cellular filter presses filter contaminated liquids down to a particle size of several micrometres.

In principle, the liquids are pressed through their own contaminants and thus purified.

The filter press consists of several filter plates arranged in a row, to which the slurry water is fed via an inlet bore. A filter cloth is stretched around these plates.

The filter plates are compressed under high pressure by a hydraulic cylinder; at the same time, the sludge is pressed from the inside to the outside of the liquid to be purified at a pressure of 7-60 bar against the filter cloths. Before a filter press is ready for use, a suitable cake will form from the sludge. During this process, the filtrate is pressed through the cloths until enough particles have combined to form a solid cake.

The time during which the liquid is not yet completely cleaned is called the sludge phase. The sludge water is fed back into the clarification process. Once the chambers are completely filled with filter cake, hardly any filtrate is filtered and the cake is removed.