- Home page

- Building materials product range

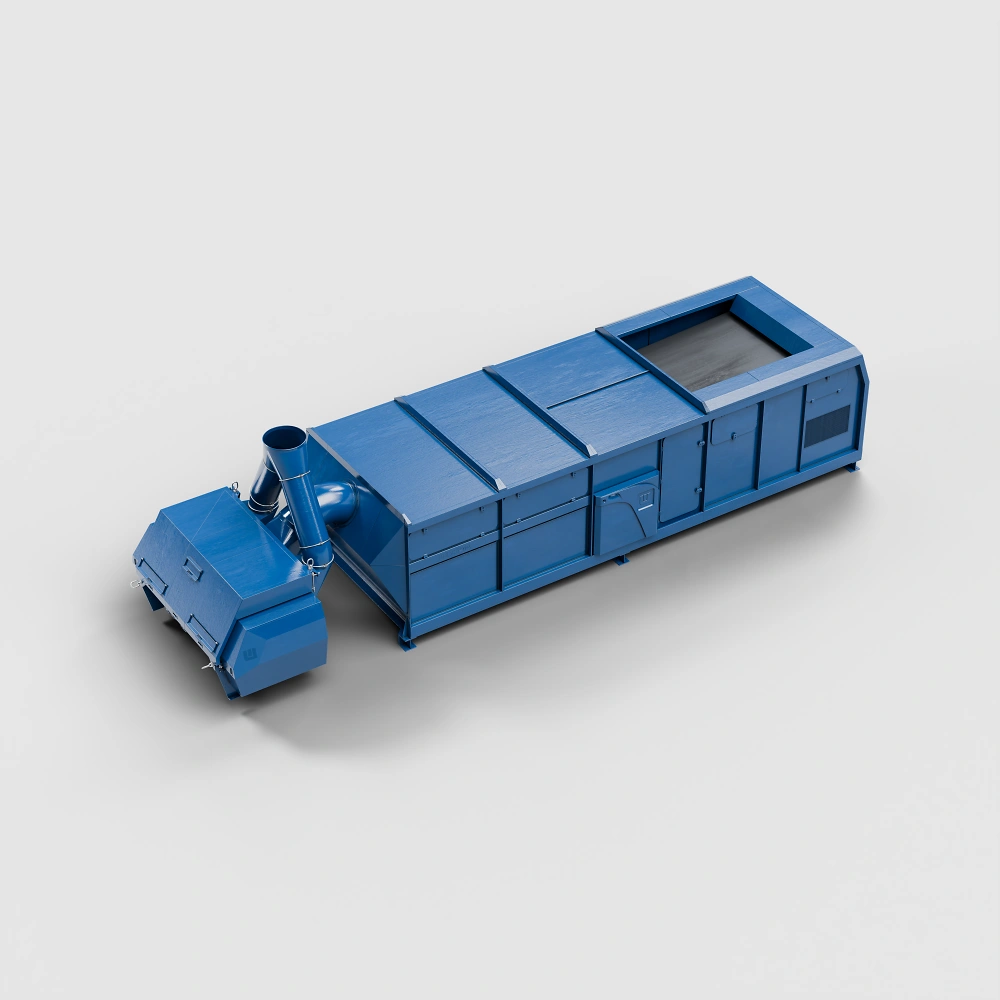

- Wind sifters

Wind sifters

Wind sifters are used to separate the material to be screened into coarse and fine fractions based on their ratio of gravity and flow resistance. The material to be screened is fed as widely and evenly as possible onto the acceleration belt, accelerated to a suitable speed and transported to the discharge edge.

An upward flow is generated by an adjustable air nozzle attached under the feed belt. This hits the upper part of the rotating drum and is forwarded laminarly into the expansion chamber. The material is separated into light and heavy material by the air flow.

The light materials are carried at high speed into the expansion chamber, where the air velocity is reduced to such an extent that the light materials fall into a container or onto a discharge belt. The heavy materials fall down into a container in front of the rotary drum in the air separator or can also be transported away on a discharge belt.

The air introduced into the expansion chamber is extracted from the upper part of the wind sifter and, depending on the application, either sucked back in by the blower or fed into a filter system.

In order to obtain high-quality recycled raw materials, special wind sifters can sort the material into three fractions with a high degree of separation accuracy.