- Home page

- Building materials product range

- Screening machine / vibrating screens

Screening machine / vibrating screens

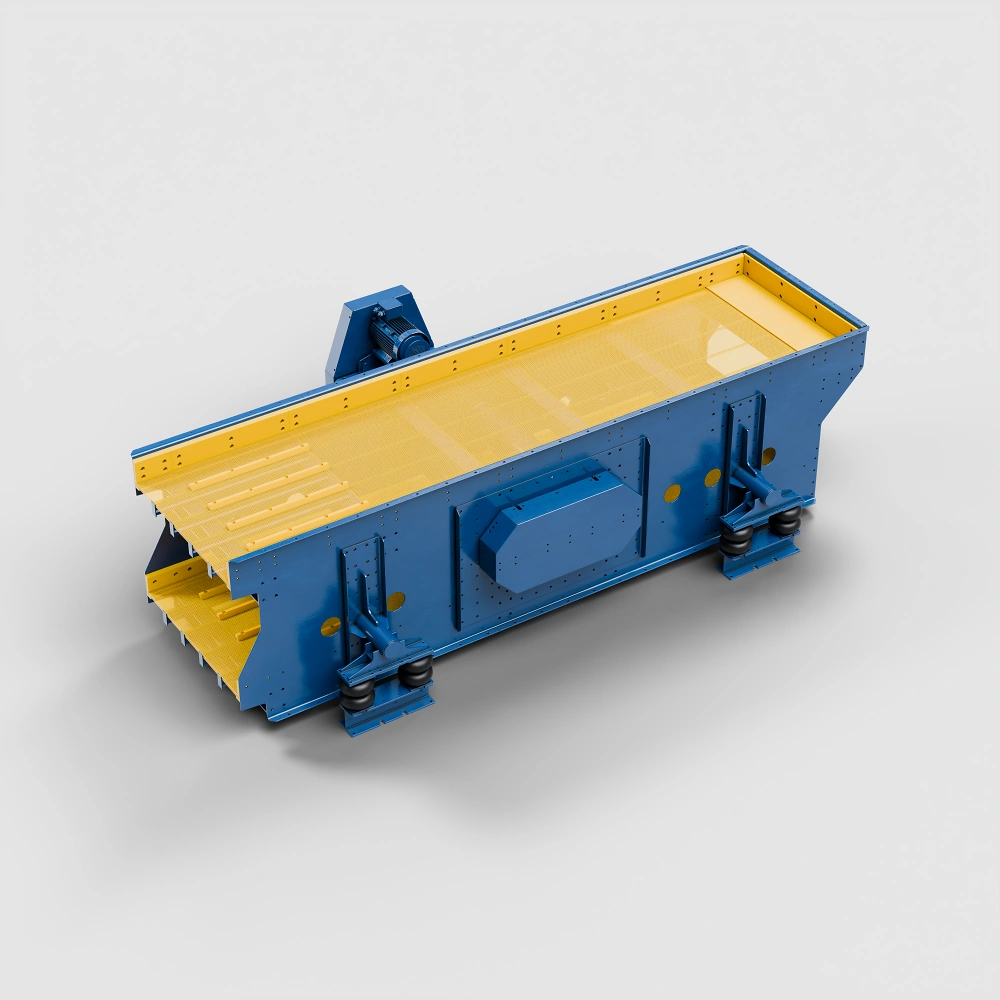

Screening machines for uniform and efficient classification of bulk material according to the desired grain sizes. A screening machine is used in material processing to classify bulk materials according to their grain size. It uses an elliptical vibrating motion that enables uniform and efficient screening. This vibrating motion ensures that the material is evenly distributed across the screen and that the different grain sizes are quickly and precisely separated through the mesh of the screen. Screening machines are often used in applications such as sand and gravel processing or recycling, where precise separation and high screening performance are required.

The elliptical vibrating screens were developed with the aim of combining the advantages of circular and linear vibrators. The vibration pattern is elliptical. Two synchronised unbalanced exciters with different masses run at the same speed in opposite directions with a specific phase shift. The shape and direction of the elliptical vibration can be adjusted to the respective operating conditions by changing the unbalanced masses and phase angle. The phase angle can be changed during operation with the electronically adjustable ellipse, but only when the machine is at a standstill with the mechanically adjustable ellipse. The machine is usually installed horizontally or with a slight downward incline.

Elliptical screening machines are designed as single-deck or multi-deck screening machines. Modular screen coverings made of PU or rubber are used as screen coverings, as are wire screen coverings, which are tensioned in the longitudinal or transverse direction. Various additional options are available, such as sprinklers, dust covers, seals, electronic braking devices and spring elements instead of steel springs.