Magnetic separator

Magnetic separators are used for the separation of materials. Through different types and designs of the machine, all circumstances can be covered.

Overbelt magnets

Permanently magnetic overbelt magnets are used when foreign iron content is to be removed automatically from bulk materials. Permanent magnets are maintenance-free and have an unlimited service life. The overbelt magnet is placed at a certain distance above the conveyor belt. The magnet, protected by a wear plate, attracts the iron parts from the bulk material. If the overbelt magnet is equipped with a discharge conveyor, the debris adheres to the underside of the belt and is continuously transported by the circulating belt that is equipped with cleats. Since the area of the tail pulley and drive pulley

is non-magnetic, the parts fall off in this zone and are collected via chutes or containers.

Magnetic drum with distribution feeder

In classic, overflowing operation, the recycling material is distributed evenly by means of a channel and fed to the rotating magnetic drum. Magnetisable particles are retained by it and discharged to the rear; the non-magnetic particles fall off.

In the lifting mode of operation, the magnetic drum rotates against the flow and is arranged in front of and above the discharge of a trough feeder. The magnetic drum picks out magnetisable particles from the flow and transports them through the rotational movement upwards to where they are discharged behind the highest point.

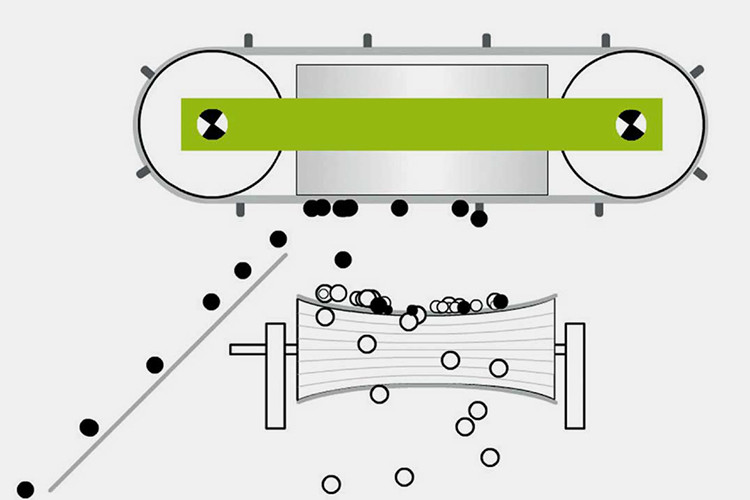

Non-ferrous separator

Non-ferrous separators are used for the recovery of non-ferrous metal. The basic structure of a non-ferrous separator consists of a short belt path, which is driven from the feed end. Its head pulley contains a fast rotating permanent magnet system – the pole system that generates high-frequency, alternating magnetic fields. These cause strong eddy currents in the non-ferrous metal parts, which now build up their own magnetic fields to counteract the external field. The non-ferrous parts are deflected from the rest of the material flow.

Scope of application

- Track maintenance/crushed rock cleaning

- Paper industry

- Sugar factories

- Brickyards

- Foundries

- Biomass power plants

- Sewage treatment plants

- Sawmills

- Compound feed plants

- General separation technology

Accessories

- Permanent magnet plate

- Permanent magnet drum

- Discharge belt

- Distribution feeder

- Material discharge