Client: Leu Anlagenbau AG

Developer: Schönegger Käsealm

Place: Allgäu

Project: conveyor system for cheese handling

Year of construction: 2007

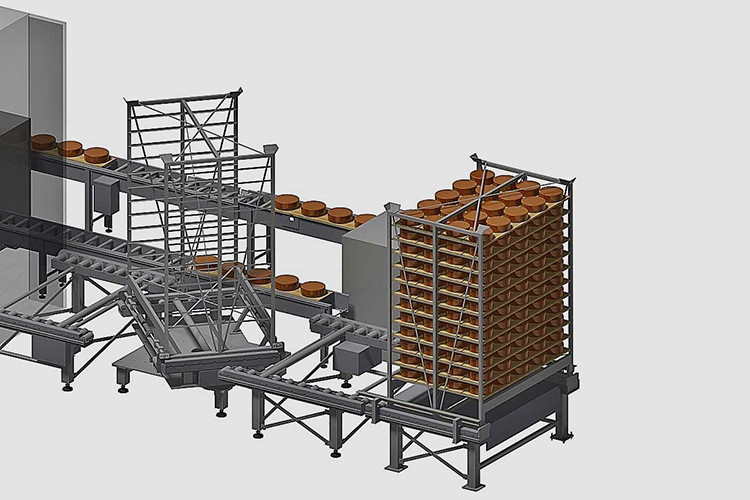

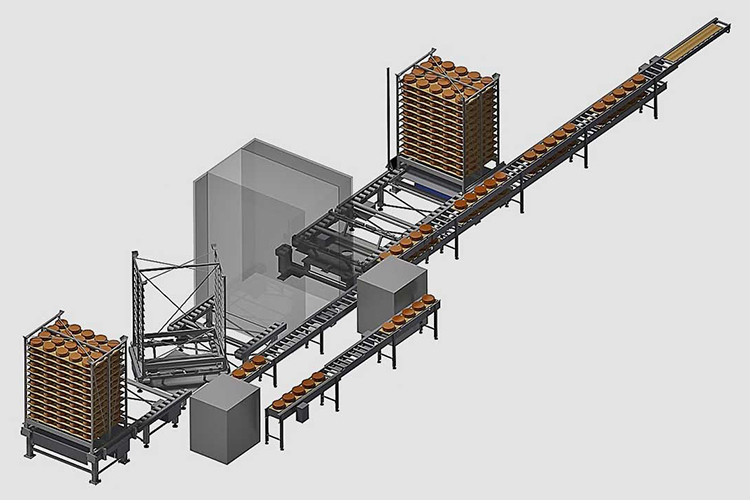

Leu Anlagenbau AG manufactures high-quality curing machines for cheeses. A system with conveying technology is produced on behalf of Schönegger Käsealm. Racks with cheeses are supplied by an automated guided vehicle (AGV), automatically cured and transferred back to the AGV.

Client: Leu Anlagenbau AG

Developer: Schönegger Käsealm

Place: Allgäu

Project: conveyor system for cheese handling

Year of construction: 2007

Project

Frei Fördertechnik AG adapted the conveyor modules to the specific requirements. The rack transport was conceived for a depositing load of 4,600 kilograms and a transport load of 2,300 kilograms. The roller conveyors for the transport of boards were specifically designed for the grabbing of the robot arms. The entire system was executed in accordance with the hygiene requirements applicable in the cheese industry. The racks are fed to the roller conveyor by automated guided vehicle systems (AGV) and destacked from double height to single height. The boards with the cheeses are provided to the robots for grabbing via a rotary table, so that they get to the curing machine and back again onto the cleaned racks.

Special features

Customised solution with adjustments at the interfaces to the robot and at the goods transfer point

Technical data

Conveyed goods 1: cheese rack

Size: 2,040 x 1,400 x 2,645 mm

Weight: 2 x 2,300 kg (double height)

Capacity: 12.5 racks/h

Conveyed goods 2: boards with cheeses

Size: 1,900 x 320 mm

Weight: 50 kg

Capacity: 10 boards/min