Client/developer: Landor AG

Place: Auhafen, Birsfelden

Project: Batch feed belt/curved conveyor belt / conveyor system

Year of construction: 2013 / 2023

Birsfelder Auhafen, a hub on the Rhine river, connects river, rail and road, making for optimal conditions for simple and inexpensive logistics. The unloading station of Landor AG was refurbished for the unloading of cargo ships with power shovels to the new silo with batch feed belt (year of construction 2013). In 2023 we are building a conveyor system in the port of Muttenz to link up with the fertiliser warehouse.

Client/developer: Landor AG

Place: Auhafen, Birsfelden

Project: Batch feed belt/curved conveyor belt / conveyor system

Year of construction: 2013 / 2023

Project 2013

As subcontractor, Frei Fördertechnik AG was responsible for the belt feeding and the curved conveyor belt. The pipe conveyor was replaced by a newly designed curved conveyor belt. The silo discharge with the belt feeder and the curved conveyor is the interface to the existing silo distribution system. The belt feeder is reversible for railway loading or loading in the existing feeding hopper with distribution system.

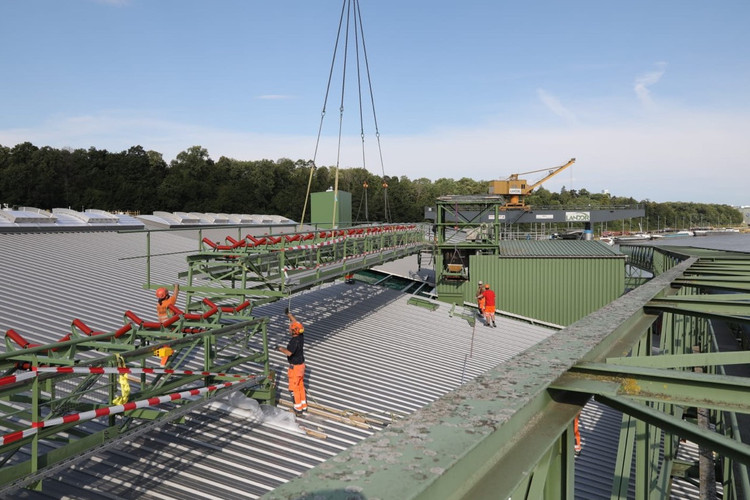

Project 2023

The scope of supply includes engineering, production and installation of the conveyor system. A total of 155 m of conveyor belts, one trolley and two platforms will be installed. In addition, adaptations are being made to the existing conveyor technology. The installation is being carried out under difficult conditions on lifting platforms under the existing roof.

Special features

Technical data

Feed material: various fertilisers

Plant feed capacity: 350 t/h, controllable

Loading capacity: 650 t/h, controllable

Installed power: 35.5 kW

Belt feeder: Belt width 1,000 mm, reversible

Curved conveyor belt: Belt width 800 mm, AA 185 m

Fritz Rothenbühler

Mitglied der Geschäftsleitung, Leiter Service

Telefon +41 31 720 56 44

Mobile +41 79 236 72 54

f.rothenbuehler@ffag.ch